VERAMTEX

Eco-friendly Textile Finishing

VERAMTEX

Eco-friendly Textile Finishing

RESEARCH & DEVELOPMENT

Since its creation, Veramtex has been active in R&D activities. It all started by the development on its own machinery in the 80’s, followed by the creation of an ammonia recovery unit in the 90’s and the design and building of a newer machine in 2000.

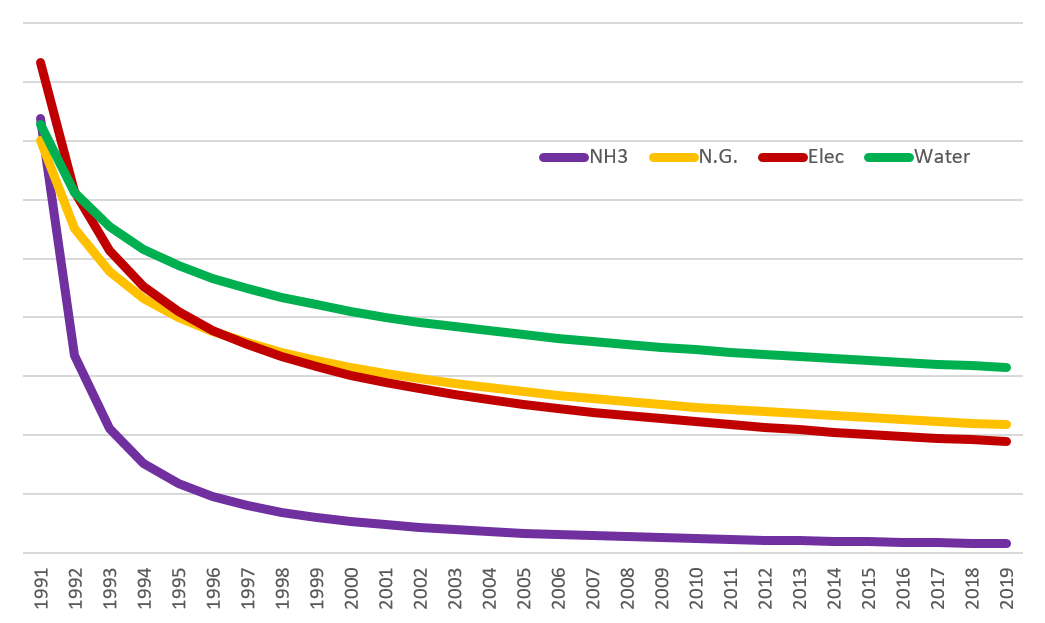

The experience gained during that period has been streamlined by several R&D projects, over the years 2000. We have been evaluating the results of our treatment on multiple fibers and products ranging from leather to wool, including paper and aramid. We also made sure to optimize various parameters of the treatment (tension, humidity, speed, ammonia elimination method, …) and of the recovery of ammonia, thereby achieving a recovery rate of more than 99 % of the used ammonia.

Besides, we significantly reduced the energy used by the process.

This experience also allowed us to diversify in the flame retardant process, started in the 2010’s.

The themes of sustainable development are also very important for us. It is therefore no wonder that Veramtex gained a first label in 2000 : öko-tex 1000, certifying the ecology of our process. That has been replaced by STeP (Sustainable Textiel Production) in 2015.

Besides, we also pioneered Life Cycle Analysis (LCA) studies, in collaboration with the ENSAIT in Roubaix. This has shown the adavantages of our treatment on the life duration of textile products (link to document).

We also are involved in several collective research programs, in two main directions : cellulose-based composites and promotion of hemp.

List recent projects

Hennep4All

This project is dedicated to the use of hemp in textile and the optimisation of the whole production process.

It has shown definite advantage of Beau-Fixe in terms of ironability .

(see pages 77 to 80 in this document : Hennep4All)

Suscomtrab

The aim of this CORNET project is « to develop sustainable fibre reinforced composites that meet the flame retardancy requirements of the transport and construction sectors, meaning that the materials are difficult to ignite, have no burning droplets and have low smoke densities and toxicities ».

Veramtex is active to develop flax-based flame-retardant textiles to be used as reinforcements in composites.

Link : Suscomtrab

FARBIoTY

The aim is similar to the previous one, (production od composites) but exclusively based on flax reinforcements. The first sector aimed at is the railway industry but the technology developed might be used in other industries : automotive, building, naval applications, wind turbines.

An ageing study of the materials is planned, as well as an LCA to assess the impact of the developed product against fiber-glass based composites.

Lien : FARBIoTY

VERAMTEX s.a.

Head Office

Zoning GALILEI

Avenue Antoon van Oss, 1 - box 9

BE-1120 Brussels - Belgium

T : +32 (0)2 262.02.34

VAT-Nr : BE 0425.291.946

Privacy Policy - Cookies - Copyright © Veramtex 2020